Meet Mark: site manager, LyondellBasell

Mark’s professional responsibilities cover a lot of territory.

He manages three facilities that make the material used in essential products that most of us rely on every day.

“We make the material that becomes bleach bottles that we all used during the pandemic. The plastic that becomes house wrap to keep moisture out of our homes. And the pipes that carry drinking water to neighborhoods. If you go to your doctor’s office or the hospital and you see plastic in the operating room. We make a lot of that material.”

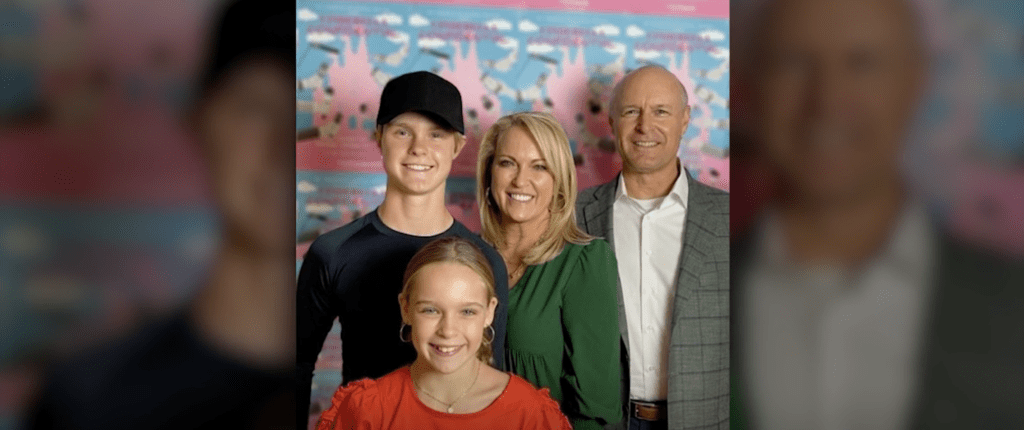

He’s proud of what his company makes. But he knows some things must change. Because his personal responsibilities cover a lot of territory, too.

“I have two young children. I have a nine-year-old daughter and 12-year-old son. We want a cleaner environment for future generations, so day by day, we are finding new ways to make what we do more sustainable for the good of everyone around the world.”

Meet Mark. One of America’s Change Makers.

Mark is inspired by the innovation he sees in his teams across the three sites.

“I see young employees that are fully engaged, trying to develop solutions to sustainability. And they’re coming up with some really brilliant ideas, ideas that we never thought of in the 50-year life of these manufacturing sites. And these ideas can help reduce our environmental footprint on the environment.”

For example:

Reducing the waste at their facilities.

“Recently, some of the engineers at the Matagorda site were taking what we call “scrap” material and trying to reprocess it. This material that we used to call scrap, now we will reuse it and turn it into finished new products.”

Reducing greenhouse gas emissions at their facilities.

“There are other ways to reduce our environmental footprint, such as reducing our CO2 emissions from equipment. We have active projects that are going to reduce emissions to the atmosphere, which is another aspect of creating a more sustainable future.”

Finding new ways to help keep the plastic material they produce where it belongs.

“The ocean starts here. That’s a phrase we commonly use at our manufacturing sites. If we lose even a single plastic pellet, it could flow downstream through the ditches and the rivers and, in our case, to the Gulf of Mexico.”

“Plastic is a very valuable material. We go through a lot of effort to produce plastic. We don’t want to lose it. It’s not right to let it get away and into the environment.”

Mark’s father inspired this drive to make things better… decades ago.

“I learned from my dad his work ethic and trying to do good things for society. He was a research and development engineer working on alternative sources of energy, looking for new ways to develop energy to support the world.”

He sees a parallel in his career… and in today’s plastic industry.

“We’re talking about sustainability and ways to minimize the environmental footprint on the planet while producing products that are useful for society.”

It all comes back to responsibility. And Mark has a lot. Hundreds of team members. Three large manufacturing facilities. A dedication to sustainability. And two kids who represent the future.

“We can reduce our environmental footprint. And we are finding ways to make that happen.”

We wish Mark and his teams continued success.