If only it were easy and efficient to harness all that energy.

To achieve a lower carbon future for ourselves and our kids, we’re going to need lots of efficient, long-lasting solar energy capacity. We’ll need a resilient power infrastructure that delivers on the promise of energy from the sun.

We’ve come a long way since 1954 when Bell Laboratories created the first silicon solar cell, which The New York Times hailed as “the beginning of a new era, leading eventually to the realization of one of mankind’s most cherished dreams – the harnessing of the almost limitless energy of the sun for the uses of civilization.”

True, that was nearly seven decades ago, and we’re obviously not quite there yet. But solar power is becoming cheaper and more efficient to produce, in part due to some innovative help from plastics.

What help?

Most solar panels are basically boxes full of photovoltaic (PV) cells that turn light into electricity. Really fragile PV cells. So here’s where plastics play an essential role, the same role they play in air bags and bike helmets and firefighter gear. These cells need protection. For a long, long time.

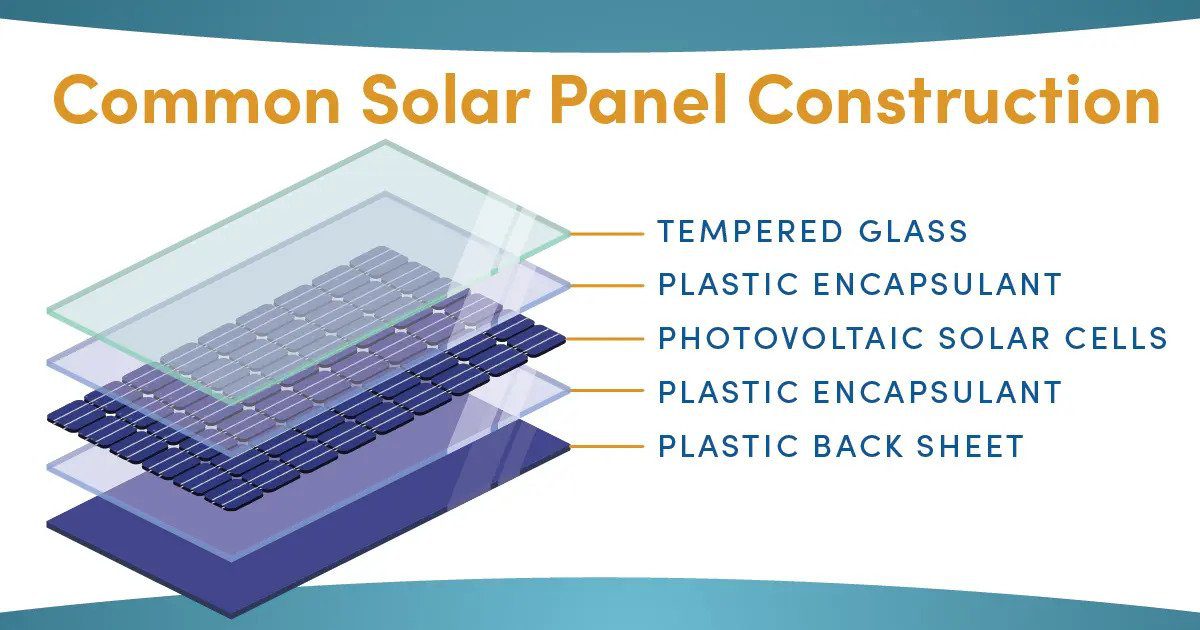

As DOE says: “In order to withstand the outdoors for many years, cells are sandwiched between protective materials in a combination of glass and/or plastics.” Here’s how that works. (Caveat: Not all solar panels are created alike.)

First, delicate PV cells are arranged face down on a plate of glass covered in a sheet of plastic “encapsulant” that safeguards the cells. Next, another encapsulant sheet is placed on the back of the cells, typically followed by a tough plastic “backsheet.” Then it’s all laminated in an oven to seal and make the system resistant to water.

NOTE: These backsheets are critical to the longevity of the solar panels. The durable plastic sheets adhere to the backside of the panel to provide protection from moisture and UV light that can damage the cells.

So the PV cells basically are enveloped in plastics to protect them from the elements. These plastics bond, seal, and insulate. And they’re transparent and UV/temperature/corrosion resistant.

In addition, plastics contribute to the essential electrical insulators, pipes, valves, and fittings needed to produce solar energy. And you can’t move electricity from solar panels (or any source) to our devices and appliances without electrical wire sheathed in plastic protection.

This is a practical example of what the scientists and engineers at plastics companies are so good at: creating efficient materials for efficient technologies that drive down greenhouse gas emissions and reduce our environmental footprint.

What’s next?

- Multiple companies provide plastics designed to replace heavier glass in solar panels, which expands the number of roofs that can physically support panels.

- Tesla is advancing its solar energy home system that relies on plastic roofing tiles.

- Flexible solar cells attached to plastic film are edging into athletic, military, and building uses.

- And plastic solar cells? Lots of research is focused on this holy grail of solar power.

Rebuilding and upgrading our energy infrastructure to produce reliable, low-carbon power will require ample new innovations. Plastic makers are supplying the materials to help us get there.

For more info on how efficient, lightweight plastics contribute to rebuilding our nation’s infrastructure, click here.