Federal Facility Upgrades for Energy Efficiency

In early 2024, the federal government launched multiple projects to upgrade its facilities for greater energy efficiency and resiliency. A significant upfront investment in 31 federal facilities is anticipated to provide a much more significant payback over time… in reduced energy use, greenhouse gas emissions and taxpayer dollars.

Like other U.S. infrastructure projects, the response from America’s plastic makers was simple: “We’re all in.” Because plastic materials are set to play a crucial role in enabling many planned upgrades.

Primary federal efforts are aimed at advancing net-zero projects. This refers to buildings that can produce as much energy as they consume, typically through renewable energy. The projects plan to achieve this “through building electrification, geothermal heat pumps, on-site solar generation, and battery energy storage among other initiatives,” as noted in the announcement.

Solar Power Generation

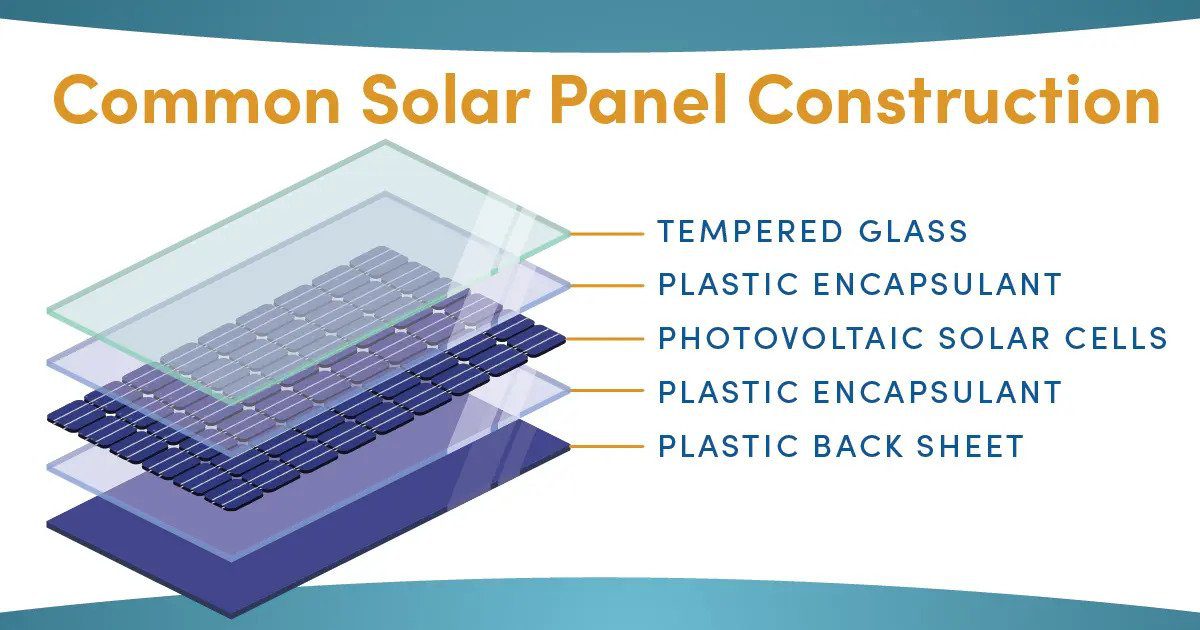

Most projects include significant scale up of solar power (including on the Pentagon). The photo voltaic (PV) cells in solar panels are reeeeally fragile. They need protection. For a long time.

Department of Energy (DOE): “In order to withstand the outdoors for many years, cells are sandwiched between protective materials in a combination of glass and/or plastics.”

PV cells basically are enveloped in plastics to protect them from the elements. These plastics bond, seal, and insulate. And they’re transparent and UV/temperature/corrosion resistant.

More info solar panels here.

Geothermal Energy

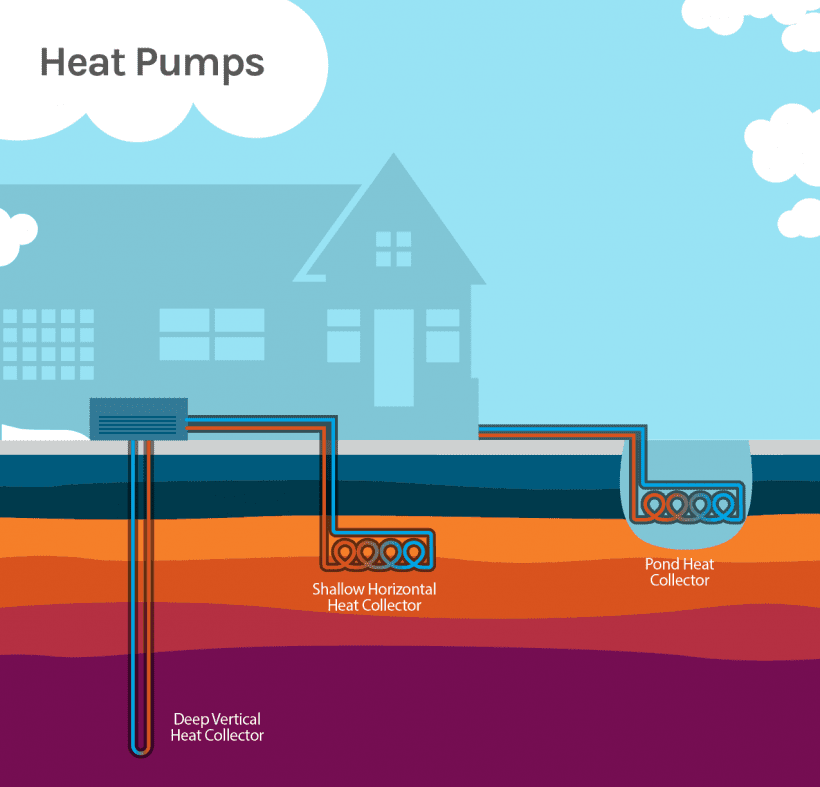

Multiple projects will expand use of geothermal energy, using the earth’s natural heating and cooling capabilities to create energy and/or heat and cool buildings. Geothermal energy is considered renewable and drives down greenhouse gas emissions compared to burning fuels for energy.

While there are multiple technologies, geothermal systems often rely on durable plastic pipes buried underground. One example:

DOE: “These pipes are filled with an environmentally friendly antifreeze/water solution that acts as a heat exchanger. In the winter, the fluid in the pipes extracts heat from the earth and carries it into the building. In the summer, the system reverses and takes heat from the building and deposits it to the cooler ground.”

Source: DOE (Office of Energy Efficiency & Renewable Energy)

Geothermal energy’s biggest drawback? The upfront expense of installation. The federal investment is designed to help overcome this obstacle.

More info on plastic pipes here.

Electrification and Plastic Sheathing

Multiple projects demonstrate the significant, ongoing shift from burning fuel for power to creating more sustainable, renewable electricity. All that electricity will need to travel untold distances – safely – through cables and wires. Most are sheathed in tough, durable, non-conductive plastic that helps protect the electrical charge… and the humans that rely on it.

More info on protecting our ability to connect to the world here.

Building Envelope Upgrades

Many projects call for upgrades that improve the building “envelope,” i.e., the physical barriers that separate the inside conditioned space from the outside world (walls, doors, roofs, windows, etc.). A lot of federal buildings were constructed decades ago when building codes were less rigorous than today, so they’re leaky and under insulated. Efficient building envelopes often rely on plastic materials to enable the switch to heat pumps, solar energy and other measures to create net-zero buildings.

More on how plastic building materials contribute to net zero buildings here.

LED Lights for Energy Efficiency

Many federal projects call for switching out old energy inefficient lighting for new energy efficient lighting. Specifically: LED lights. Traditional filament bulbs use/lose most of their energy as heat. Light-emitting diodes (LEDs) typically lose much less energy to heat and are protected by transparent, tough, durable plastic, so they can be used indoors and outdoors. The plastic also helps insulate the LEDs, providing additional protection against overheating and fire hazard.

Our water delivery systems. Our energy generation and distribution. Our cars and trucks. Our homes and buildings.

As our nation sets about rebuilding our infrastructure and restoring our resilience, plastic will play an outsized role. America’s plastic makers are all in and ready to contribute.