Meet Jennifer, vice president of technology, Pregis. One of America’s Change Makers.

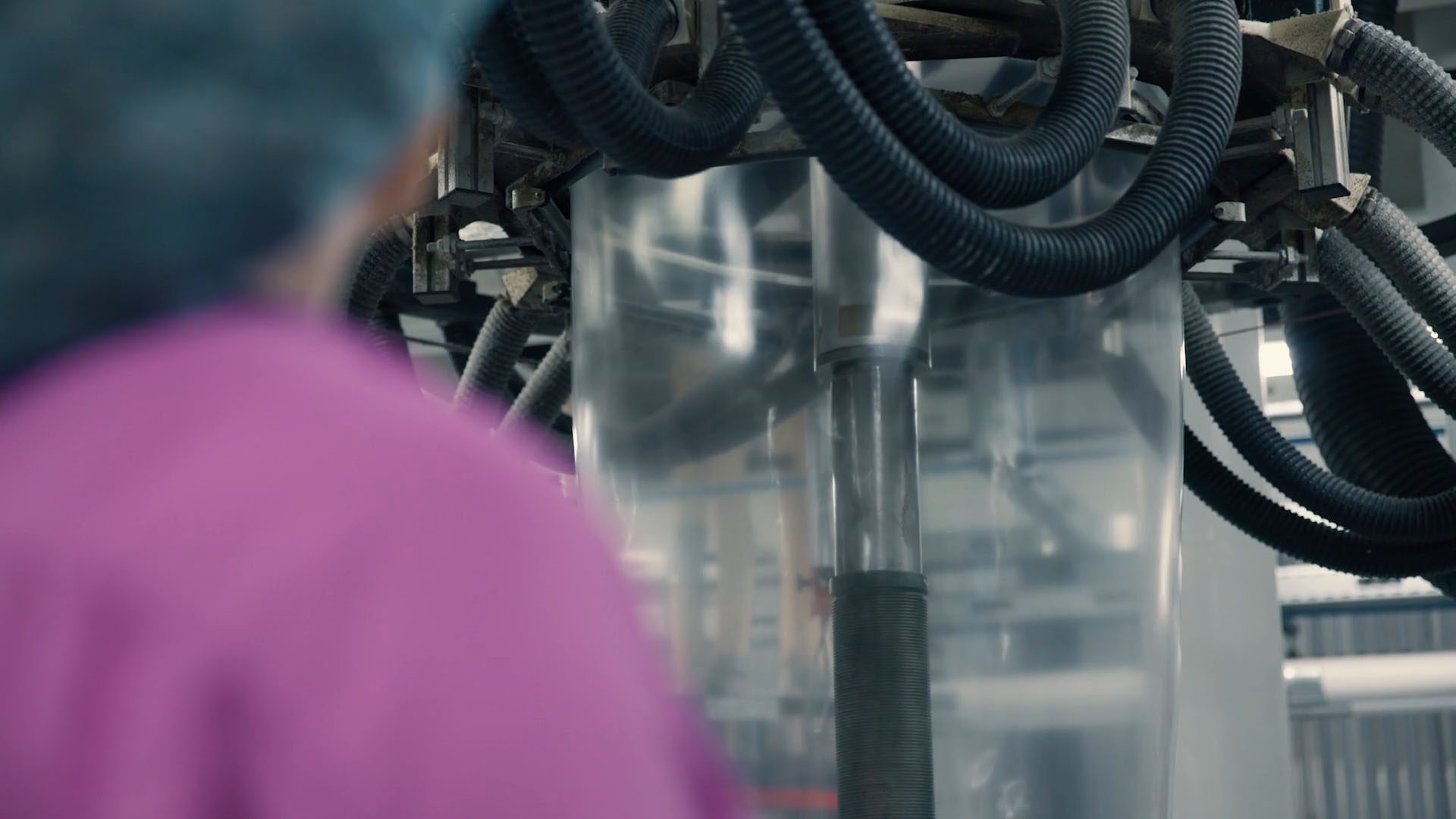

Those packages that land on your doorstep? Jennifer helps make the packaging that protects those products.

“Today everybody’s buying products from online retailers. Of course, you want those products to arrive safely.”

A big part of Jennifer’s role as vice president of technology at Pregis is helping make packaging that does its job – delivering a product clean and intact – while limiting its environmental impact.

“We’re all consumers. We buy things, and we buy even more things online now, particularly post Covid. So, at my company we’re being a little bit more critical about what’s actually needed to protect the product. What that means to me is focusing on the right amount of resources and using less.”

Lightweight, Efficient Plastic Film Packaging

Much of the packaging she helps create is made from very thin, lightweight plastic film/wrap that uses very little material. Jennifer’s job is to continually make that efficient packaging even more efficient. To continually improve its sustainability.

“Sustainability means being really purposeful about what we design in terms of packaging, that it’s enough to protect the product but also something that can be collected and reused. Because one of the wonderful things about plastic is its ability to be reprocessed.”

Reusing plastic is the next step in improving the sustainability of plastic film packaging.

“How do we make plastic packaging more sustainable? That’s my job. One of the ways we’re doing that is including recycled content.”

“It’s not uncommon for us to take our own manufacturing leftovers and reprocess them back into the packaging that we make. That’s just good manufacturing process.”

“But now we’re including post-consumer plastic, which is plastic at the end of its life that’s being diverted from landfills.”

More Efficient: Recycled Content in Film Packaging

One of Jennifer’s customers came to her with a big sustainability task.

“We had a customer ask us to take a film packaging that we currently supply for them and make it with 80% post-consumer recycled plastic. We all looked at each other and thought this can’t be done. We generally don’t see anything above 25% recycled content. But it’s something that we took on as a challenge.”

A challenge. Because reusing plastic can be a bit challenging when making thin film packaging.

“There can be a bit of an issue with collecting enough plastic film and processing it back into film. We found a really good partner who was processing post-consumer plastic film, and we tested it and incorporated it into our design for one of our packaging products. And as a result of all those tests and experiments, we have a high-performing cushioning product with 80% recycled content that performs as well as the original product.”

It was a big deal. For Jennifer and improving sustainability.

“I feel a huge sense of accomplishment. Instead of saying, well, we can’t do that, we asked, what are the things we need to do to support this development?”

“The fact that we’re able to demonstrate that we can incorporate 80% post-consumer plastic in a thin film shows its potential. So now we can divert more plastic from going to landfills and put it back into new products.”

High Performance Plastic, High Performance Coach

Jennifer has an interesting analogy between her two “creative” roles: work and winterguard.

“In addition to working in plastics, I’ve been a coach for winterguard for 25 years. It’s kind of like when you see a high school marching band, and then there’s the color guard waving the flags, and you put them in a gymnasium, and then set the performance to a piece of music.”

“It could be any theme. We’ve done movie characters, we’ve done flight attendants. Actors. So you can be anything you want. It just depends on where the creative staff takes it.”

It’s all about high performance.

“Winterguard has progressed to a point where it’s very much a performance. So I’m not only a coach working with high performer students, but I’m also invested in high performance plastic packaging.”

“I’m about making plastics perform better.”

We wish Jennifer and her colleagues continued success.