Meet Diane, sustainability director, consumer packaging North America, Berry

Is it just a cup? Or is it the start of a new journey?

“Our customers come to us and say, ‘Hey, I want to be more sustainable.’ But all our customers are in different places in this sustainability space. And so, the journey looks different with each of them.”

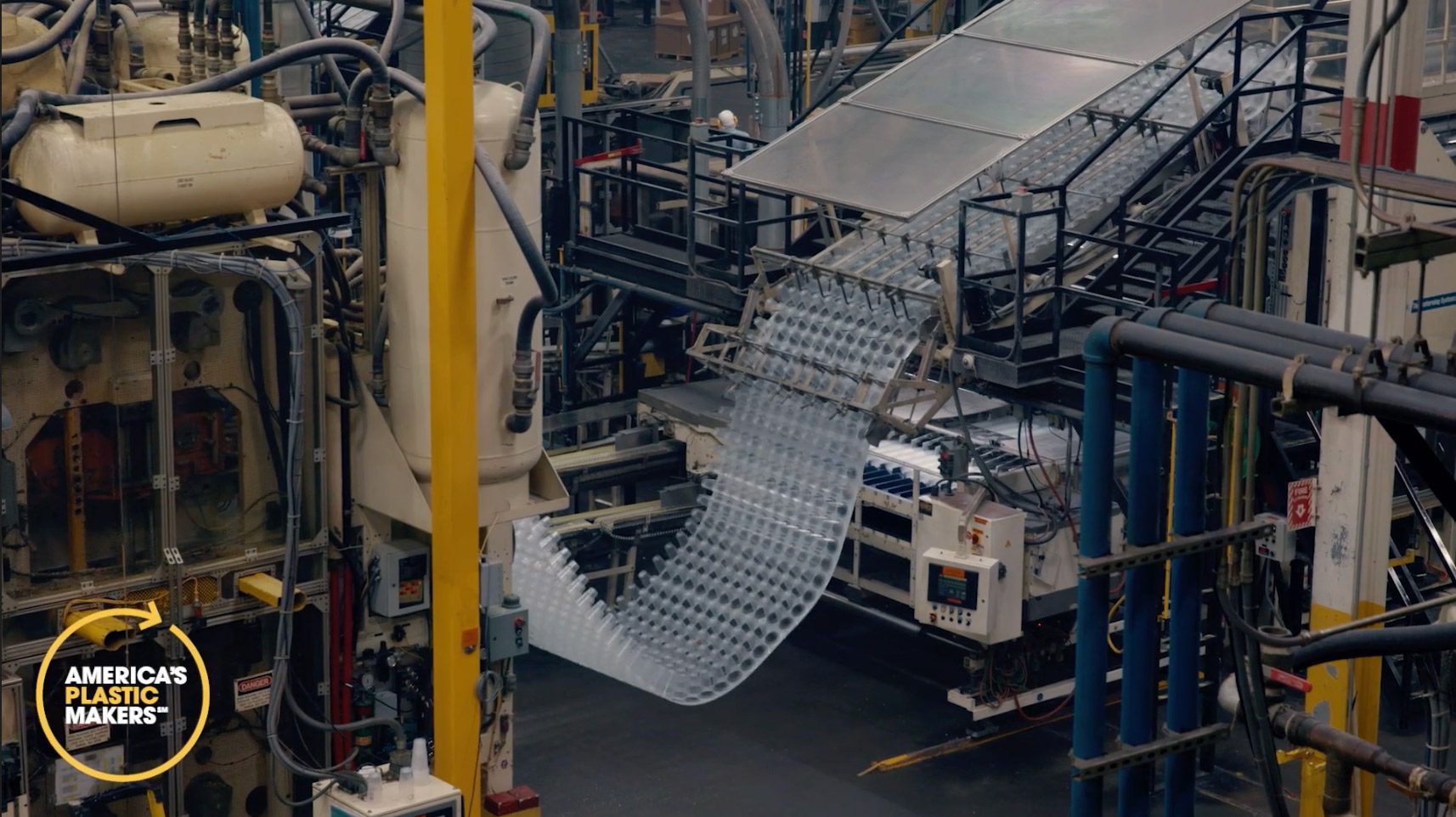

For one big customer, that journey led to a first-of-its-kind advancement in sustainability. All while designing a product with recycled content that’s also designed for recycling.

“We had a project with a large, fast-food company that wanted to use advanced recycled material in its drink cups.”

“Advanced” recycling breaks down plastic to its molecular level, to its building blocks that can be used to make top-quality new plastic. Again and again. Which reduces the need for fossil-based raw materials.

“By using that advanced recycled material, you can choose how much you put into packaging. This particular customer is choosing to put 20% into their cup.”

Someday those cups will journey across the nation to serve people at a well-known restaurant chain. So every day, those customers will be able to help that company shrink its environmental footprint.

And that’s just one cup at one company. As sustainability director for consumer packaging North America at Berry Global, a large packaging maker, Diane is guiding multiple companies on their journey toward sustainability. She’s helping plastic makers and their customers make sustainable change.

Meet Diane. One of America’s Change Makers.

Advanced recycling is one path on that journey. But there are others.

“We’re now moving into this era where people are looking for sustainable options. From our perspective, what that looks like is either bio-based, mechanically recycled or advanced recycled materials. Any number of sustainable solutions exist. And so ultimately, our goal is to decouple from virgin fossil fuel.”

A good example of one of those solutions? Chocolate.

“We have a customer that sells chocolates that are very sensitive to absorbing taste and odor. They were considering adding recycled material to their packaging, but they were a little concerned about its effect on the chocolate.”

While that sounds like a simple switch, packaging is actually quite complex.

“We were able to go out and find the sources of post-consumer recycled material, PCR, bring that in, do sampling, create some of those containers with that material, and then give that to the customer to allow them to do all the testing that they needed to validate that this marriage of that PCR material into that container would work for their product.”

How did the packaging turn out?

“It’s done very well. Ultimately, we were able to show that by incorporating these types of recycled materials, we didn’t sacrifice anything about the packaging. It still performed the same as it did when it used a virgin material. But now we have

the opportunity to use this more sustainable material to package their chocolate.”

And even with the added recycled plastic, that packaging can still be recycled.

“Through all this effort of incorporating more sustainable materials, the big challenge is making sure we’re designing something to make it recyclable. Ultimately, we want to make sure that any time we’re incorporating recycled materials, we’re still maintaining the integrity of the packaging itself and we’re not changing the ability to recycle it. So by pulling in the right types of circular, more sustainable materials, we can maintain that design for recycling.”

Diane takes some inspiration from one of her hobbies that requires persistence and patience – beekeeping. She loves to watch the busy little bees doing what they do best: making honey happen.

She and her colleagues knew they could make more sustainable packaging with advanced or mechanically recycled plastic. It just required a bit of persistence and patience.

“We just needed to make it happen.”

For drink cups. Chocolate packaging. Product dispensers. And much more. Diane’s helping make sustainable change.

“This is fun. We all want to do the right thing for the planet. I really enjoy this role because I have an opportunity to make a change.”

Keep making that change, Diane.

We wish Diane continued success on her journey.