Meet John, Commercial Director, North America, Trinseo

“I wanted to give back by serving our country.”

John learned many things during his three and a half years as an Army Ranger. But one thing sticks out.

“The one thing I learned from that experience and through many lessons in my life is to never give up. You may fail, and that’s okay. But you can never give up in any task. Persistence and perseverance are the most important traits.”

John has translated that spirit through many roles (small town mayor, finance, operations) to his present role, as part of a growing movement that requires persistence and perseverance. Sustainability.

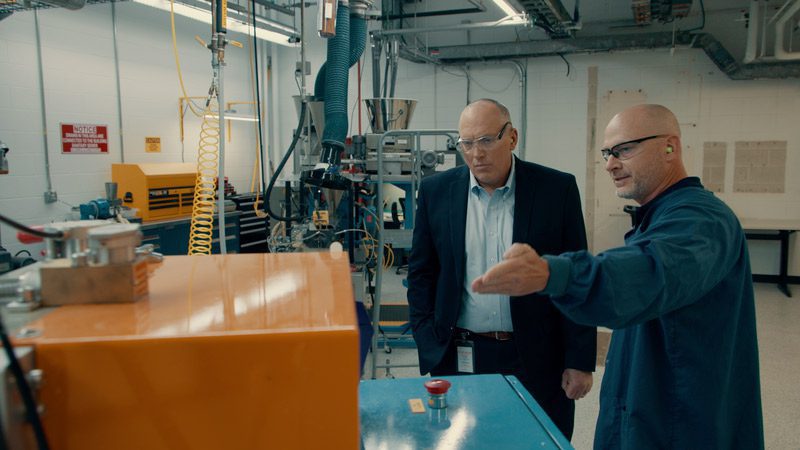

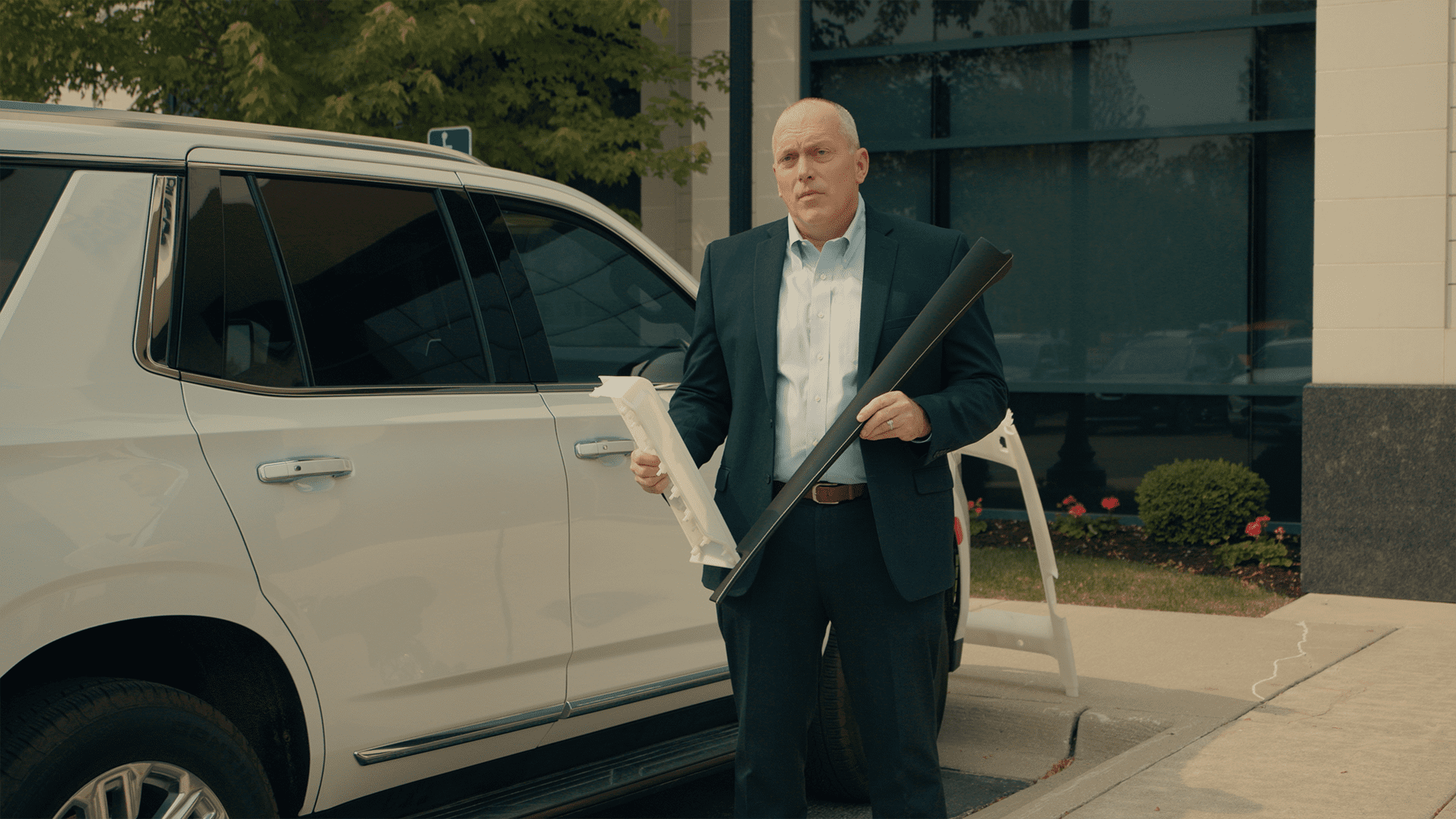

Most of the materials his company makes are used in the millions of cars and trucks that we drive.

“Our plant in Detroit runs 24/7. Eighty percent of the products made here are used for automobiles. Their bumpers, spoilers, air bags, door panels, control panels and items throughout the interior of the vehicles.”

While most people aren’t aware, the materials in these car components help improve sustainability. As North American commercial director for Trinseo, a large plastic maker, John is helping our nation’s automakers improve fuel efficiency and sustainability. Through “lightweighting” and championing recycled and bio-based plastics.

Meet John. One of America’s Changemakers.

To improve fuel efficiency in our nation’s cars and trucks, automakers have been turning more and more to strong yet lightweight

plastic and composite materials.

“Plastics are used in the automotive industry to lightweight vehicles. The lighter the vehicle, the better the gas mileage or the longer the charge on the batteries for electric vehicles. So, the lighter the vehicle, the further it can go.”

That translates into fewer tailpipe and greenhouse gas emissions.

“That’s important for sustainability. It allows less carbon to be produced both by gas cars and by EVs. Vehicles are going to be part of our daily lives. The way to make them more fuel efficient, more sustainable, is through plastics.”

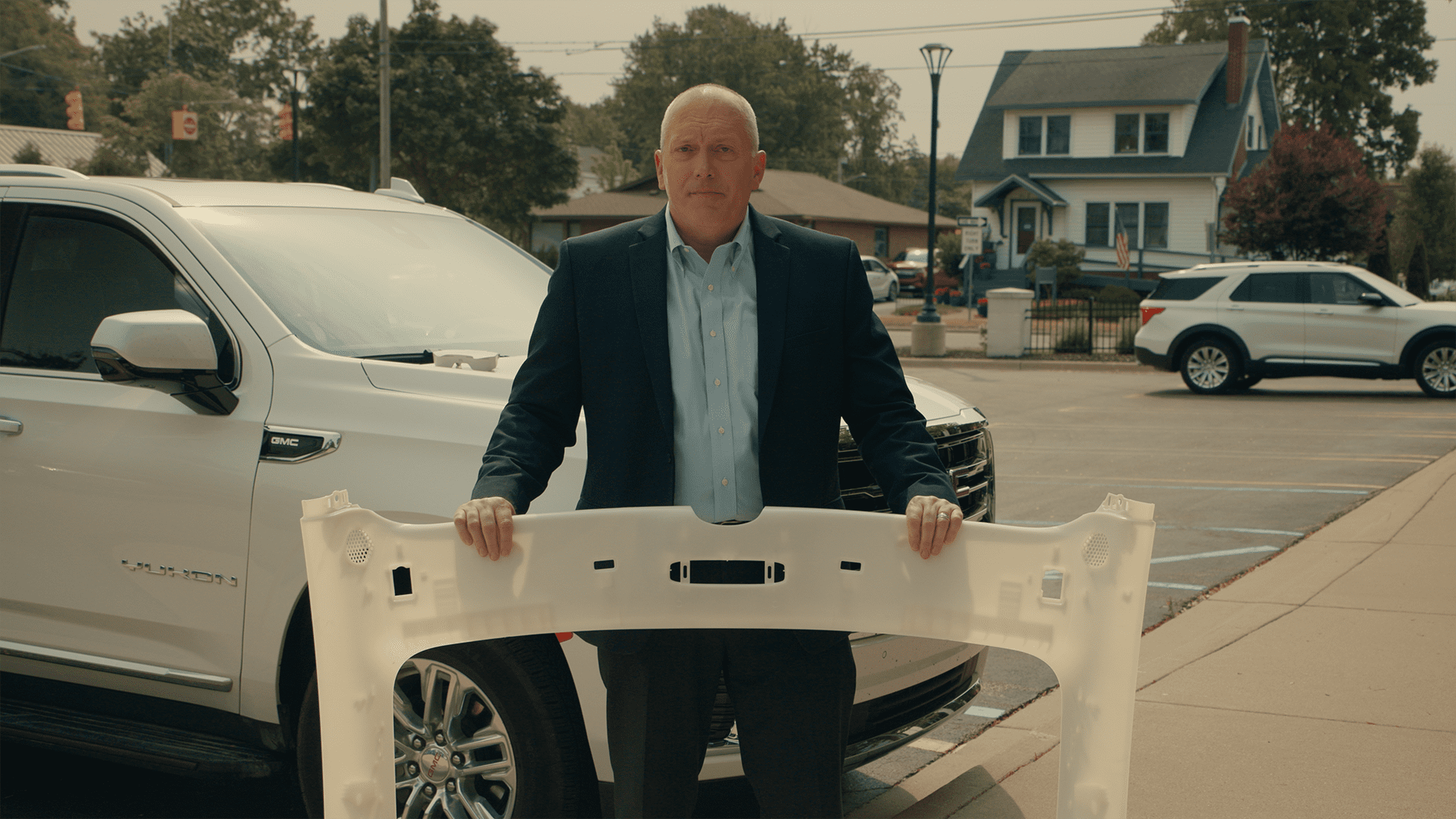

The changes over the decades in our cars and trucks have been dramatic.

“Years ago, automobiles were built primarily with metal and steel. Now we use plastics to help lightweight them. In a large vehicle that weighs maybe 6,000 pounds, if it was metal instead of plastic, it would probably weigh close to 10,000 pounds. That would limit the gas mileage. Instead of around 20 miles to the gallon, you’d be talking ten miles to the gallon or less.”

And John is digging deeper into sustainability.

“Lightweighting has been a big part of plastics in automobiles for years. But the key now is that we’re taking those same plastics and adding recycled materials and biomaterials, more sustainable products into the same vehicle.”

“So, now not only are we extending the range of gasoline vehicles or battery charged vehicles, but we also are making them more sustainable in the long run. We’re making a more sustainable product for the road ahead.”

John thinks collaboration between plastic makers and auto makers is just getting started.

“The goal would be to make an electric vehicle as sustainable and recyclable as possible, then to have the EV be recycled completely.”

Changing the old way of doing things requires persistence and perseverance. And John has five personal reasons to continue using those traits he developed long ago.

“I’m passionate about sustainability because I have five kids, and I want the world to be a good place for them to grow up and have kids and grandkids themselves. So, my goal is to make these vehicles as sustainable as possible.”

Persistence. Perseverance. Keep driving sustainable change, John.

We wish John continued success.